Asset

Failure

Maintenance

Action

Maintenance Management – Basis for Productivity, Energy Efficiency and Safety

Maintenance and asset management is of central importance for the company’s value creation.

The DaIM function supports all planned and unplanned asset management processes over the entire life cycle of an asset. With asset management, all relevant aspects and risk factors are captured and form the starting point for HSE specific functions.

Highlights

- Hierarchical asset tree enables easy navigation

- Implementation of planned maintenance

- Automatic reminders

- MTBF, MTTR and further KPI

- Freely configurable message chains in the Andon system

- Simple failure reporting and notification of service staff

- Asset and order prioritization

- Asset-related storage of internal and external protocols in the document management system

- Access to the asset documentation by the technician at the machine

- fFree checklists for documentation of asset maintenance

Asset

The hierarchically structured asset and asset management is the central pivot in the management system. All technical & organizational parameters of a asset are recorded in it and form the starting point for the evaluation of risks, environmental, safety or energy aspects.

Failure

Failure reports for assets can be generated manually or via IoT devices and assigned to the responsible employees. Automatic failure statistics are available at any time. Failure documentation (incl. photo documentation) is done mobile on site or conveniently at the workplace. Service teams work directly in the management system.

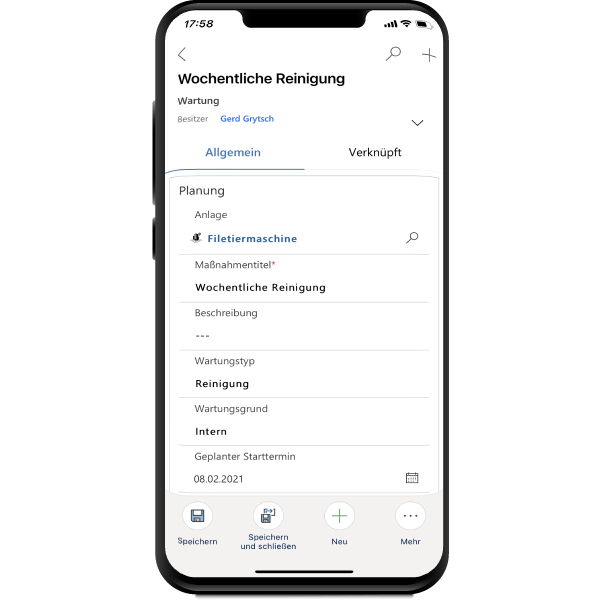

Maintenance

Maintenance activities to increase asset availability and safety are planned in the maintenance calendar. Deadlines and legal requirements are taken into account on a asset-specific basis. Maintenance orders are generated from DaIM and reported directly in the system.

Action

All initiated actions from the respective functions in DaIM are brought together centrally with reference to the source. Root cause analysis and implementation of corrective and preventive actions are process-driven. This ensures continuous improvement of the entire management system.

The core components of DaIM

App

A central app for communication and collaboration in Microsoft Teams. With the data-based implementation of all standard requirements, processing is possible anytime and anywhere.

Documents & Processes

Securely edit documented information and processes efficiently, approve and authorize effectively, and keep them linked to the DaIM App's protected data.

Connector

Efficient handling of existing data by connecting data sources based on hundreds of proven data connectors. Deep insights by integrating all relevant data from the enterprise across all standards.

Review

Real-time management review at the click of a mouse. Minimize the effort for recurring evaluations. Compare the results of your management reviews.

Digital Auditor & AI

AI is not only about certification readiness of your management systems, but also about changing the way your employees work. With the Digital Auditor and the Improvement Engine you transfer your management system approach into the digital age.

Audit Mining

Real-time management review at the click of a mouse. Minimize the effort for recurring evaluations. Compare the results of your management reviews.

Innovative Technologies

The functional fusion of leading collaboration tools makes DaIM unique and the most advanced management system in the world today.

Functions

Asset management

Complex asset management over the entire life cycle

Audit management

Planning, execution and reporting from a single source

Compliance management

Binding obligations and material evidence at a glance

Document management

Collaborative work and database-supported management of electronic documents

Incident management

Intuitive recording and seamless tracking of events

Hazardous materials management

Safe handling of hazardous materials through systematic processes

Maintenance management

Preventing malfunctions through efficient maintenance

Key figure management

Flexible key figure system for monitoring business processes

Context management

Identifying and anticipating the expectations of interested parties

Measures management

Centralized control of corrective and preventive measures from all sources

Means of measurement management

Mapping of means of measurement hierarchies and maintenance of means of measurement capability

Process management

Identification, visualization, documentation, control and optimization of business processes

Resource Management

Organization of competencies, authorities and tasks for management teams

Risk management

Monitoring opportunities and risks in an intelligent way

Training management

Demand-driven training organization and record keeping

Scopemanagement

Clearly define scopes and exclusions through transparent scoping